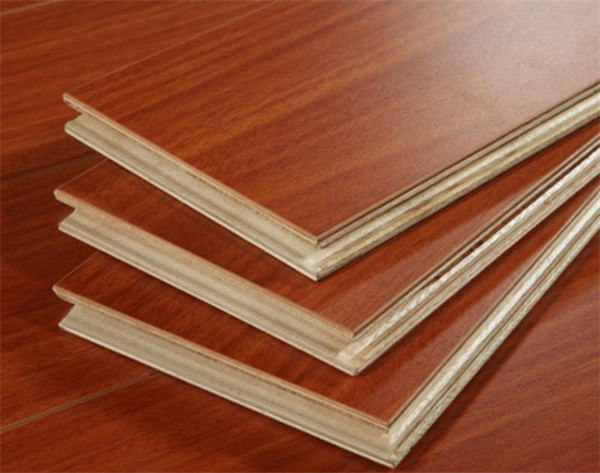

Composite Floor MUF Urea Resin

- Product Information

MUF Urea Resin is a high-molecular synthetic resin with excellent performance. It is synthesized through specific chemical reactions using urea, formaldehyde and other raw materials as the main raw materials. This resin has good adhesion, heat resistance and water resistance, and the formula and process can be adjusted according to different needs to meet the requirements of various industrial applications. In many fields, especially in wood processing, composite material manufacturing and other industries, MUF Urea Resin plays an indispensable role and is one of the important adhesive materials in modern industrial production.

Composite Floor MUF Urea Resin Parameters:

| Name | Melamine Urea Formaldehyde Resin Powder |

| Model | 190/190A |

| Shelf life | 1 year |

| Product form | white powder |

| Weight | 25kg |

| Timber moisture | optimally 8-10%±≤2% |

| Hot-pressing temperature | 80-120℃ |

| Hot-pressing pressure | 8-16kg/cm² |

| Hot-pressing time | 1 min/per mm in plate thickness |

| Performance | Boiled at 100℃ for 4 hours(190) / Boiled at 100℃ for 6 hours(190A) |

| Amount of curing agent added | 2-5‰ of the glue already blended |

| Without curing agent, activity period | 24 hours |

| Without industrial flour and curing agent, activity period(190A) | 48 hours |

| Curing agent has been added, activity period | 3 hours |

| Coating quantity | depending on the texture and smoothness of plate, generally 150-180g m²(single side) |

Composite Floor MUF Urea Resin For Use:

1. Prepare a container, stirring tools, and 25kg of room temperature water (add the water twice).

2. Dissolving glue powder: First pour 15kg of water into the container, then pour 25kg of resin powder into the water and stir to dissolve. Stir into a paste until the glue powder does not agglomerate, then add the remaining 10kg of water and fully stir to form a glue solution.

3. The mixed glue is used after 1 hour of waiting, and the effect is the best.

4. According to the production requirements of the product process, it can be mixed with additives such as curing agent(Ammonium chloride) .

5. During use, increase or decrease the ratio of resin powder to water according to the moisture content of the board and the local climate.

6. Amount of industrial flour added: 20-25% of the glue already blended.(190A to add)

Composite Floor MUF Urea Resin Features:

High Bond Strength

Composite Floor MUF Urea Resin has excellent bonding performance and high bonding strength, which can ensure close adhesion between the layers of the composite material. According to industry standard tests, the peel strength of the composite board made of this resin under standard conditions is much higher than that of ordinary adhesives, which effectively prevents material delamination and ensures the integrity and durability of the product.

Heat-resistant stability

Composite Floor MUF Urea Resin can still maintain stable performance in high temperature environments. During the hot pressing process, even at a hot pressing temperature of 80-120°C, it can ensure good bonding between the resin and the substrate, and will not decompose or fail due to high temperature. Its heat-resistant stability meets relevant industry standards, ensuring that products such as composite floors can maintain good physical properties even in high temperature environments during use, without problems such as debonding and deformation.

Water and boiling water resistance

Composite Floor MUF Urea Resin has excellent water resistance. After being boiled in 100°C boiling water for 4 hours (190) or 6 hours (190A), it can still maintain good bonding effect without debonding or expansion. This feature makes it particularly suitable for products such as composite flooring in humid environments or that need to be frequently exposed to water. It meets the industry's strict requirements for water-resistant composite materials and effectively extends the service life of the product.

Environmentally friendly and low free formaldehyde

During the production process, the content of free formaldehyde is strictly controlled to meet the requirements of environmental protection standards. Its free formaldehyde emission is far lower than the limit value specified in relevant national standards, ensuring that the impact of the product on human health and the environment during use is minimized, meeting the needs of modern consumers for environmentally friendly products, and can be used in the production of interior decoration materials.

Easy to operate

Composite Floor MUF Urea Resin is easy to use and simple to operate. It is a white powder and is easy to mix evenly with other raw materials. During the hot pressing process, parameters such as hot pressing temperature 80-120°C, hot pressing pressure 8-16kg/cm², hot pressing time 1 minute/mm board thickness are easy to control, and no complicated equipment and process are required. Ordinary hot pressing machines can meet production needs, greatly improving production efficiency and reducing production costs.

Moderate activity period

Composite Floor MUF Urea Resin has an activity period of 24 hours without adding curing agent, and an activity period of 3 hours after adding curing agent. The activity period of 190A product is 48 hours without adding industrial flour and curing agent. This moderate activity period not only ensures that the resin has sufficient operating time for mixing, coating and hot pressing during the production process, but also completes the curing reaction within a reasonable time, ensuring the balance between production efficiency and product quality, and meeting the actual needs of industrial production for the activity period of adhesives.

Reasonable coating amount

Depending on the texture and smoothness of the substrate, the coating amount of Composite Floor MUF Urea Resin is generally 150-180 g/m2 (single side). This coating amount can ensure sufficient bonding strength between the resin and the substrate without causing excessive waste, which can effectively control costs. At the same time, a reasonable coating amount also helps to ensure the appearance quality and physical properties of the product, so that it can meet the use requirements and have good market competitiveness.

Composite Floor MUF Urea Resin Application:

1. High Water Resistance

The primary purpose of our Composite Flooring MUF Resin Powder is to ensure a very high degree of water resistance, thus guaranteeing that composite floorings retain their stability and durability even under highly moist conditions. Therefore, this makes it a perfect option for places with moisture levels such as kitchen, bathroom or basement where moisture is expected. This calls for the use of our MUF Resin Powder which will stop your flooring from being spoilt by moisture.

2. Stronger Adhesive Strength

Our Composite Flooring MUF Resin Powder creates a strong bonding layer between components of composite floors leading to increased strength significantly. It ensures that the floors do not break apart when they are subjected to pressure hence ensuring that the carpets last long in effect. You can rely on our MUF Resin Powder for forceful adhesion required by high performing floors.

3. Suitable for Heavy Traffic

Our Composite Flooring MUF Resin Powder is tough enough to withstand heavy foot traffic making it suitable for both residential and commercial use. It guarantees that this flooring does not wear out easily or get damaged in any way even if many people are using it over time.

4. Easy and Fast Application

This makes it easy to apply during manufacturing process since our Composite Flooring MUF Resin Powder has been designed to be user-friendly hence saving you time. Just in case one may need faster delivery times at reduced price, then this efficiency will help cut down production period while giving good quality end products Choose us for efficient production without sacrificing quality through use of our MUF Resin Powder.

5.Eco-friendly Production

Being one of the best producers of China’s MUF resin powder, we are dedicated towards sustainable production practices. Owing to its environmentally friendly materials and methods used during the manufacture, our Composite Flooring MUF Resin Powder is an eco-friendly option for companies that are concerned about the environment.

Composite Floor MUF Urea Resin FAQ:

For what purpose is Composite Flooring MUF Resin Powder used?

Composite Flooring MUF Resin Powder serves as adhesive during the manufacturing of composite flooring. This guarantees strong bonding, water resistance and increased life span of the flooring for both residential and commercial use.

What does MUF Resin Powder do in terms of durability for composite flooring?

MUF Resin Powder creates a robust bond between floors and therefore increases their strength within the realm of composite flooring. It makes them more resistant to abrasion, moisture, and other environmental conditions making it sustainable for long term usage.

Can Composite Flooring MUF Resin Powder work in high-moisture areas?

Yes, our Composite Flooring MUF Resin Powder is engineered to provide excellent waterproofing properties hence suitable for application in areas like kitchens, lavatories and basements where moisture can be a concern.

How does Composite Flooring MUF Resin Powder fare environmentally?

Our MUF resin powder, is manufactured using environmentally friendly methods thus epitomizing our commitment to sustainability in production which renders it a dependable choice for those who seek reduced ecological footprints.